Celuka Formex Sintra Sheets offer rigidity and a smooth surface, perfect for signage and displays. Gluing PVC foam boards allows for custom configurations with strong, durable bonds. Additionally, PVC doors are weather-resistant and low-maintenance, providing excellent insulation and security for any space.

Specification

| Name | Pvc crust foam board |

| Density | 0.35~0.9g/cm |

| Color | White、Customized |

| Place of Origin | Guangzhou,China |

| Main Material | 100% PVC |

| Regular Size | 1220x2440mm (4'x8') or customization |

| Service | OEM |

| Size | 1220*2440mm,1220*1830mm,1000*2000mm,915*1915mm,Customiztion |

| After sales service | 24 Hours On-Line Support |

| Thickness | 1mm,2mm,5mm,8mm,10mm,12mm,15mm,18mm,20mm,etc. |

| Application | Advertising Signage,Outdoor Advertising,Signboard Production, |

| Payment | 30% deposit, 70% balance before shipment. |

| Packing | Carton box or wooden pallet or PE Bag package. |

Product detail

Real-World Fire Resistance of PVC Boards

PVC boards, including PVC Celuka board, PVC board sheets, and UV foam board, offer strong fire resistance, making them ideal for many applications. They meet safety standards by minimizing ignition risks and flame spread.

The Role of PVC Boards in Waterproof Construction

PVC boards, such as PVC crust foam boards and PVC coated boards, are vital for waterproof construction. They resist moisture, preventing water damage. The Celuka Formex Sintra Sheet enhances durability, making it ideal for wet environments and ensuring reliable protection against leaks.

Exploring the High Hardness of PVC Boards

PVC boards, particularly the Celuka Formex Sintra Sheet, excel in combining hardness with flexibility. This makes them suitable for various applications. When gluing PVC foam boards, the strong bond maintains structural integrity, while PVC doors benefit from this balance, offering both durability and ease of use in different environments.

PVC Board Sheets: Durable and Environmentally Friendly

PVC boards, such as PVC crust foam boards and PVC coated boards, are often misperceived in terms of water resistance. The Celuka Formex Sintra Sheet is highly durable and moisture-resistant, making it ideal for various applications, and supports eco-friendly construction with long-lasting, waterproof solutions.

Edge Treatment Techniques for PVC Board Cutting

For cutting PVC boards like PVC crust foam boards and PVC coated boards, using the right techniques ensures smooth, fray-free edges. Tools designed for clean cuts enhance the quality of the Celuka Formex Sintra Sheet, improving both aesthetics and durability in various applications.

Why Customization Matters in PVC Board Applications

Customization is crucial for PVC board applications, such as Celuka Formex Sintra Sheets and gluing PVC foam boards. Tailored dimensions enhance fit and function, particularly for PVC doors, ensuring optimal performance and aesthetics in diverse settings. This flexibility meets specific project needs effectively.

Why choose us?

(1)High Quality: Our Celuka Formex Sintra Sheets are manufactured to the highest standards, ensuring durability and reliability for all applications.

(2)Customization Options: We offer tailored solutions, including gluing PVC foam boards, to meet specific project requirements and dimensions.

(3)Versatile Applications: Our products, including PVC doors, are suitable for a wide range of environments, making them ideal for both residential and commercial use.

Raw material

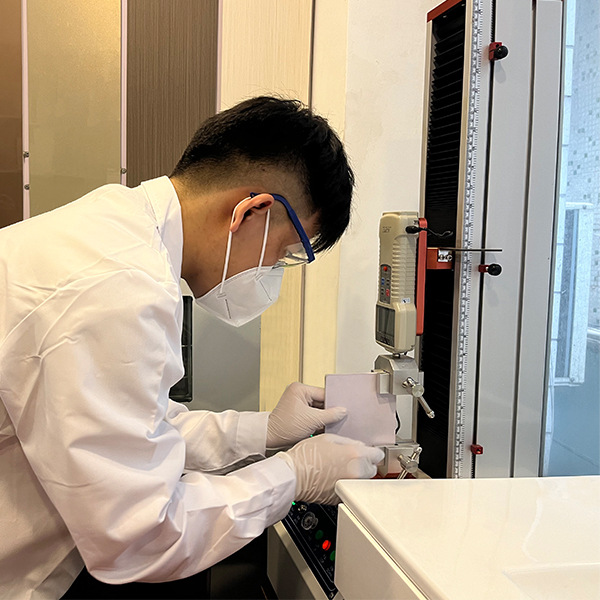

R&D Center

Production equipment

Product warehousing

Production process

(1)Material Selection: We use high-quality raw materials, including gluing PVC foam boards and PVC crust foam boards, ensuring a strong foundation for our products.

(2)Manufacturing Techniques: Advanced extrusion and molding processes are employed to create PVC coated boards with precise dimensions and desired properties.

(3)Quality Control: Rigorous testing and quality checks are implemented throughout the production process to ensure durability, performance, and compliance with industry standards.

Cutting machine tool

Product production

Product production

Product production

Packing & Delivery

(1)Secure Packaging: We use sturdy packaging materials for Celuka Formex Sintra Sheets and gluing PVC foam boards to prevent damage during transit, ensuring products arrive in perfect condition.

(2)Efficient Handling: Our team is trained in careful handling techniques, making sure that every PVC door and board is loaded and unloaded with utmost care to maintain quality.

(3)Timely Delivery: We prioritize on-time delivery, utilizing reliable logistics partners to ensure your orders of PVC boards reach you promptly and efficiently.

Wooden pallet packaging

PE bag packaging

FTL

FCL

Applications

(1)Interior Design: PVC coated boards and Celuka Formex Sintra Sheets are ideal for creating stylish wall panels, providing a modern look with excellent durability in residential and commercial spaces.

(2)Signage: Gluing PVC foam boards are widely used for signage due to their lightweight nature and ability to withstand outdoor elements, making them perfect for both indoor and outdoor advertising.

(3)Furniture Manufacturing: The versatility of PVC boards allows them to be used in furniture production, offering a waterproof and easy-to-clean surface suitable for kitchens and bathrooms.

Screen

Strorage rack

Sign

Green Plants

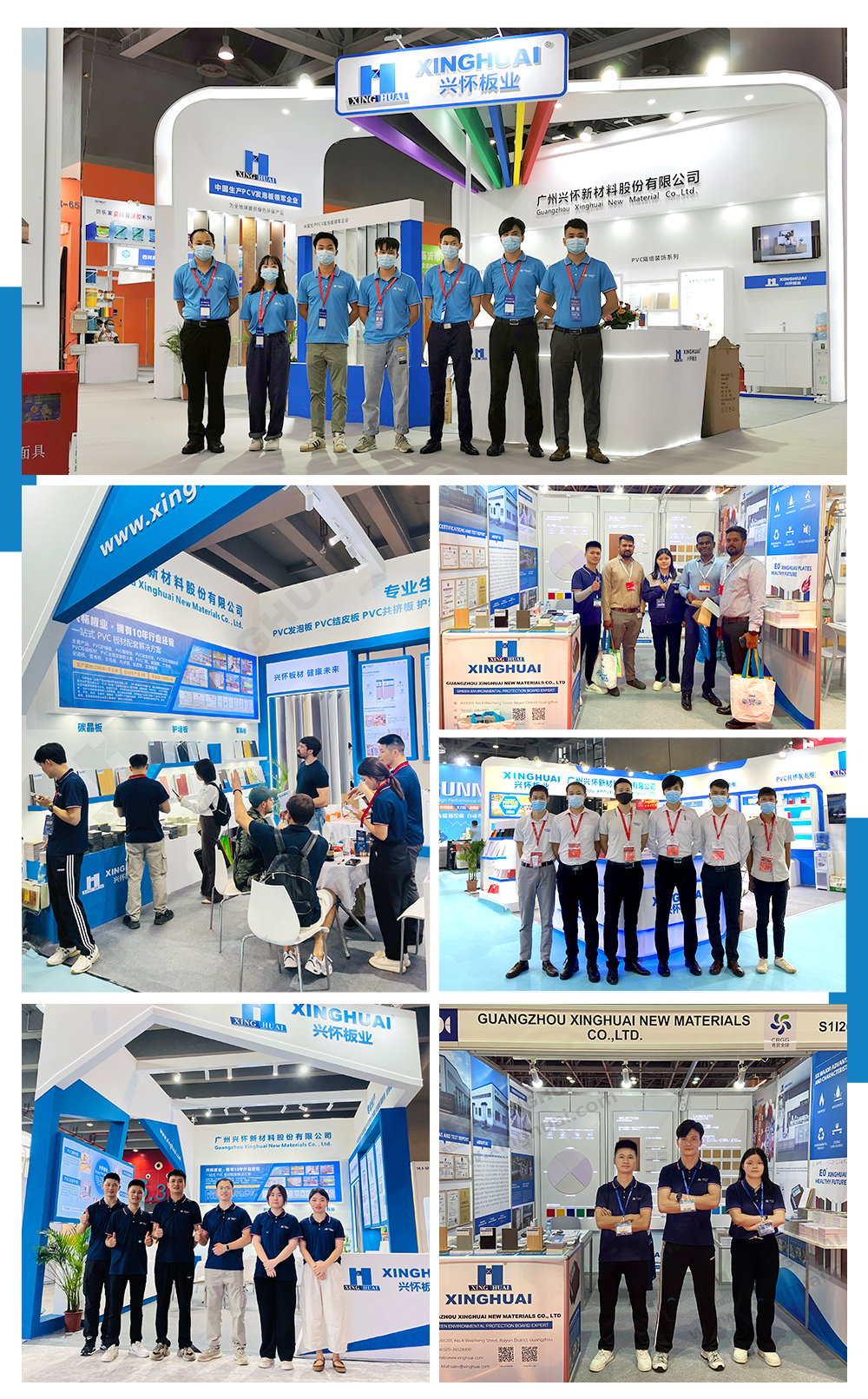

Our exhibition

(1)Market Exposure: Showcasing products like Celuka Formex Sintra Sheets and gluing PVC foam boards at trade shows increases visibility, attracting potential customers and distributors who might not be aware of your offerings.

(2)Networking Opportunities: Exhibiting PVC doors and other products allows for direct interaction with industry professionals, fostering valuable connections that can lead to collaborations and partnerships.

(3)Feedback and Trends: Engaging with visitors provides insights into customer preferences and market trends, helping to refine products and strategies based on real-time feedback from industry stakeholders.