Our PVC foam boards, including 1-30mm PVC form board and PVC expanded foam board sheets, benefit from a skilled R&D team and advanced production equipment. This ensures high-quality PVC foam panel sheets and waterproof PVC foam wall panels, delivering durability and versatility for various applications.

Specification

| Name | Pvc crust foam board |

| Density | 0.35~0.9g/cm |

| Color | White、Customized |

| Place of Origin | Guangzhou,China |

| Main Material | 100% PVC |

| Regular Size | 1220x2440mm (4'x8') or customization |

| Service | OEM |

| Size | 1220*2440mm,1220*1830mm,1000*2000mm,915*1915mm,Customiztion |

| After sales service | 24 Hours On-Line Support |

| Thickness | 1mm,2mm,5mm,8mm,10mm,12mm,15mm,18mm,20mm,etc. |

| Application | Advertising Signage,Outdoor Advertising,Signboard Production, |

| Payment | 30% deposit, 70% balance before shipment. |

| Packing | Carton box or wooden pallet or PE Bag package. |

Product detail

PVC Celuka Board: A Fire Safety Choice

PVC Celuka boards are a smart choice for fire safety, offering superior resistance compared to traditional materials. Their robust structure, seen in products like PVC expanded foam board sheets and PVC foam panel sheets, enhances fire performance.

Understanding the Limits of PVC Board Water Resistance

PVC boards, like 1-30mm PVC form boards and PVC expanded foam board sheets, offer good water resistance but have limits. While they handle moisture well, prolonged exposure to standing water can lead to degradation. Proper care is essential for maintaining their longevity in wet conditions.

Choosing the Right High Hardness PVC Board

When selecting high hardness PVC boards, consider options like 1-30mm PVC form boards and PVC expanded foam board sheets. These materials provide excellent durability and impact resistance, making them ideal for demanding applications.

PVC Boards and Indoor Air Quality: What You Need to Know

PVC boards, such as PVC foam panel sheets and PVC foam wall panels, are great for indoor air quality. They emit low levels of volatile organic compounds (VOCs) and resist moisture, helping prevent mold. Their waterproof features enhance durability and ensure a healthier indoor environment.

The Advantages of No-Fuzz Cuts in PVC Manufacturing

No-fuzz cuts in PVC manufacturing, especially for products like PVC foam wall panels, ensure clean edges and enhanced aesthetics. This precision reduces the risk of fraying, improving durability.

Custom Sizing Options: Enhancing Aesthetic Appeal in PVC

Custom sizing options for PVC foam wall panels enhance aesthetic appeal by allowing tailored designs to fit any space perfectly. These panels are not only versatile in size but also waterproof, making them ideal for areas exposed to moisture. This combination ensures a stylish and durable solution for both residential and commercial applications.

Why choose us?

(1)Quality Assurance: Our PVC foam wall panels are manufactured to the highest standards, ensuring durability and long-lasting performance, even in waterproof applications.

(2)Customization: We offer a variety of sizes and finishes, allowing you to tailor products to meet your specific design requirements.

(3)Expert Support: Our knowledgeable team is ready to assist you at every step, providing guidance on material selection and installation for optimal results.

Raw material

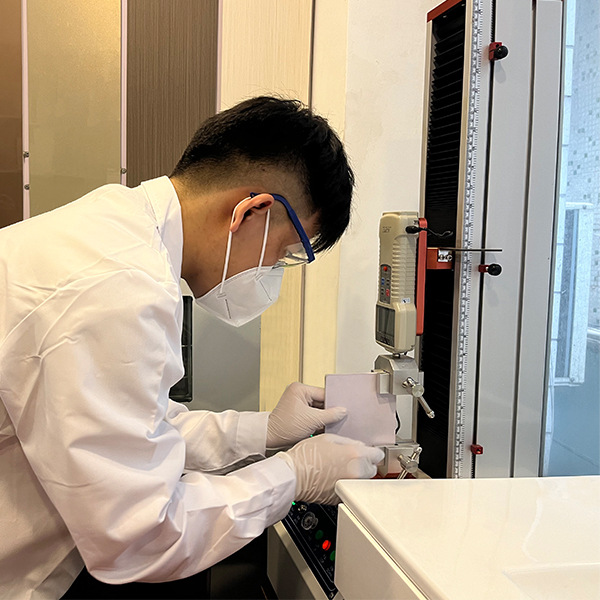

R&D Center

Production equipment

Product warehousing

Production process

(1)Material Selection: High-quality raw materials, including 1-30mm PVC form board, are carefully chosen to ensure durability and performance in various applications.

(2)Foaming Process: The PVC is mixed with additives and subjected to a foaming process, creating expanded foam board sheets. This step ensures a lightweight yet sturdy product.

(3)Finishing and Quality Control: After shaping, each PVC foam panel sheet undergoes rigorous quality control checks to meet industry standards, ensuring a reliable final product ready for use.

Cutting machine tool

Product production

Product production

Product production

Packing & Delivery

(1)Protective Packaging: Each 1-30mm PVC form board is carefully wrapped to prevent damage during transit, ensuring that the products arrive in perfect condition.

(2)Efficient Handling: PVC expanded foam board sheets are stacked securely and labeled for easy identification, facilitating quick loading and unloading processes.

(3)Timely Delivery: Our streamlined logistics ensure that PVC foam panel sheets are delivered on schedule, meeting the needs of our customers without delays.

Wooden pallet packaging

PE bag packaging

FTL

FCL

Applications

Construction: The 1-30mm PVC form board is widely used for building projects, offering lightweight yet durable solutions for walls and ceilings.

Signage: PVC expanded foam board sheets are perfect for signage due to their smooth surface, allowing for vibrant printing and easy customization.

Interior Design: PVC foam panel sheets are increasingly popular in interior design, used for decorative wall panels and furnishings, combining aesthetics with practicality.

Screen

Strorage rack

Sign

Green Plants

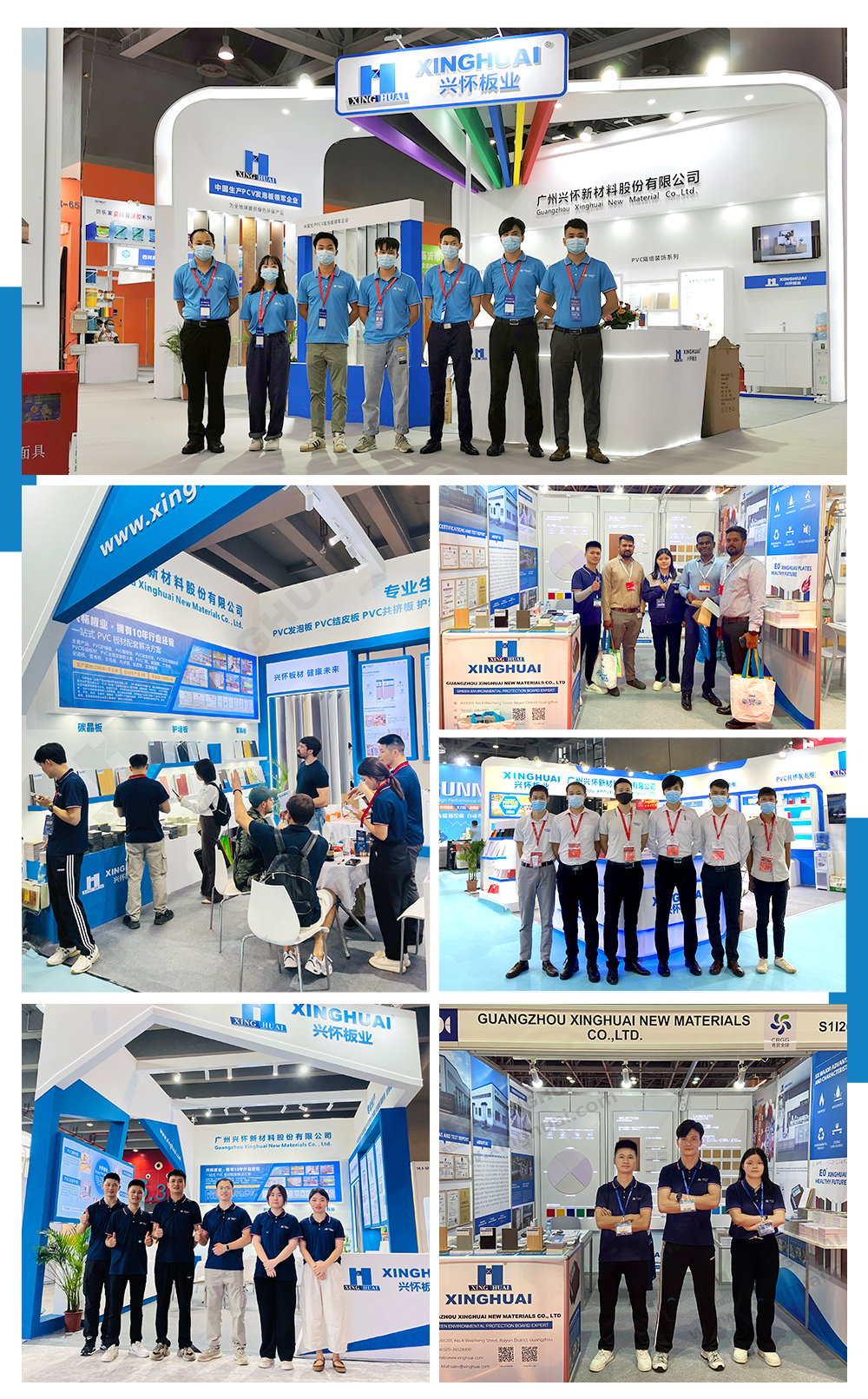

Our exhibition

(1)Networking Opportunities: Exhibiting PVC foam panel sheets and waterproof wall panels allows businesses to connect with potential clients, suppliers, and industry experts, fostering valuable relationships.

(2)Product Exposure: Showcasing PVC foam wall panels highlights their innovative features and applications, attracting attention from a broader audience and generating interest in new markets.

(3)Market Insights: Trade shows provide firsthand feedback from attendees, helping companies understand market trends and customer preferences, which can inform future product development and marketing strategies.