What Are the Common Thickness Specifications of PVC Foam Boards on the Market?

Introduction to PVC Foam Boards

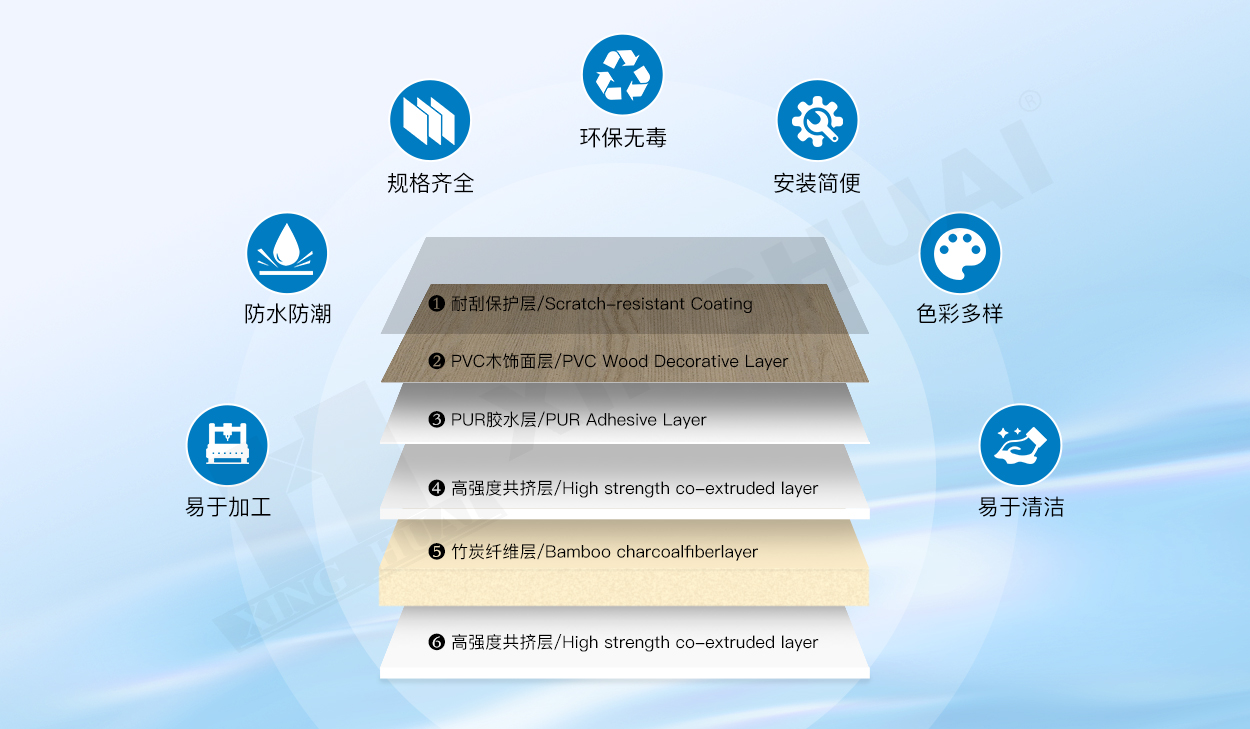

PVC foam boards, including the well - known PVC celuka board plastic foam board, have become extremely popular in various industries due to their unique properties. These boards are made from polyvinyl chloride (PVC) and are foamed during the manufacturing process, plastic foam board resulting in a lightweight yet durable material. Among the different types, plastic foam board hard PVC board and compressed PVC board also hold significant market shares, celtec expanded pvc and celtec expanded PVC is another variant that is widely recognized.

Understanding the Types of PVC Foam Boards

PVC Celuka Board Plastic Foam Board

The PVC celuka board plastic foam board celtec expanded pvc is a type of PVC foam board that has a distinct structure. It is produced using a special celuka process, plastic foam board which gives it a more uniform cell structure compared to some other foam boards celtec expanded pvc. This results in better mechanical properties such as higher strength and better dimensional stability. The celuka process also helps plastic foam board in achieving a smoother surface finish, making plastic foam board it suitable for applications where a high - quality appearance is required celtec expanded pvc,plastic foam board like in interior decoration and signage celtec expanded pvc.

Hard PVC board is known for its high density and rigidity. It is made by adding a large amount of plasticizers and other additives to the PVC resin during the manufacturing process. This makes it extremely strong and resistant to bending and deformation. Hard PVC board is often used in applications where structural integrity is crucial, such as in the construction of partitions, plastic foam board cabinets, and furniture. It can also withstand harsh environmental conditions, making it a reliable choice for outdoor applications.

Compressed PVC Board

Compressed PVC board is created by applying high pressure to the PVC foam during the manufacturing process. This compression reduces the volume of the foam cells, resulting in a denser and more compact board. Compressed PVC board has improved surface hardness and better resistance to scratches and impacts. It is commonly used in applications where a smooth and hard surface is needed, such as in the production of display stands, trade show booths, and high - end packaging.

Celtec Expanded PVC

Celtec expanded PVC is a well - established brand in the PVC foam board market. It is produced through an expansion process that creates a closed - cell structure. This structure gives celtec expanded PVC excellent thermal and acoustic insulation properties. It is also lightweight and easy to fabricate, making it a popular choice for applications such as wall cladding, ceiling tiles, and automotive interiors.

Common Thickness Specifications of PVC Foam Boards

Thickness Range for General Applications

In the market, PVC foam boards, including PVC celuka board plastic foam board, hard PVC board, compressed PVC board, and celtec expanded PVC, come in a wide range of thicknesses. For general - purpose applications, the most common thicknesses start from 3mm. This thin thickness is often used for applications such as making small decorative items, model - making, and as a backing material for posters and banners.

Moving up, 5mm thickness is also quite popular. It offers a bit more strength and durability compared to the 3mm boards and is commonly used in interior decoration projects, such as creating wall panels and partition dividers. The 8mm thickness is another frequently seen option. It provides a good balance between strength and weight, making it suitable for applications like making simple furniture components, such as table tops and cabinet doors.

Thicker Specifications for Heavy - Duty Applications

For more heavy - duty applications, thicker PVC foam boards are required. The 10mm thickness is often used in the construction of outdoor signs and displays. It can withstand the elements and provide a stable base for large - scale graphics. The 12mm thickness is commonly found in the manufacturing of trade show booths and exhibition stands. It offers enough strength to support heavy equipment and displays while still being relatively lightweight for easy transportation and assembly.

The 15mm thickness is a popular choice for applications that require high strength and durability, such as in the construction of industrial partitions and storage cabinets. It can handle significant loads and is resistant to impact and wear. The 19mm thickness is often used in the production of large - scale furniture, such as desks and workbenches. It provides a solid and stable surface that can support heavy objects.

Special Thickness Requirements

In some specialized applications, even thicker PVC foam boards are needed. For example, in the construction of marine structures, 25mm or thicker PVC celuka board plastic foam board, hard PVC board, compressed PVC board, or celtec expanded PVC may be used. These thicker boards offer better buoyancy and resistance to water damage. In the aerospace industry, custom - made PVC foam boards with specific thicknesses are used for insulation and structural components, depending on the requirements of the aircraft design.

Factors Influencing Thickness Selection

Application Requirements

The most important factor in selecting the thickness of a PVC foam board is the application requirements. If the board is going to be used for a decorative purpose where strength is not a major concern, a thinner board like 3mm or 5mm may be sufficient. However, for applications that require the board to support weight or withstand external forces, such as in furniture making or construction, thicker boards like 15mm or 19mm are more appropriate.

Load - Bearing Capacity

The load - bearing capacity of the PVC foam board is directly related to its thickness. Thicker boards can generally support more weight without deforming or breaking. For example, a 10mm PVC celuka board plastic foam board can support a certain amount of weight, but a 19mm board of the same type can support a much larger load. This is crucial in applications where heavy objects will be placed on the board, such as in industrial storage racks or workbenches.

Environmental Conditions

The environmental conditions in which the PVC foam board will be used also play a role in thickness selection. If the board will be exposed to harsh weather conditions, such as strong winds, rain, or extreme temperatures, a thicker board is recommended. For example, outdoor signs made from celtec expanded PVC are often thicker to ensure they can withstand the elements over an extended period. In contrast, if the board will be used indoors in a controlled environment, a thinner board may be adequate.

Conclusion

In conclusion, the market offers a wide variety of thickness specifications for PVC foam boards, including PVC celuka board plastic foam board, hard PVC board, compressed PVC board, and celtec expanded PVC. The choice of thickness depends on the specific application requirements, load - bearing capacity needs, and environmental conditions. By understanding these factors, consumers and manufacturers can select the most appropriate thickness of PVC foam board for their projects, ensuring optimal performance and durability. Whether it's for a simple decorative item or a large - scale industrial application, there is a PVC foam board thickness available to meet the demand, with each type of board having its own unique advantages and characteristics that contribute to its suitability for different uses.