Our PVC colour board is a high-quality solution for various applications, offering durability and versatility. Available in multiple colors, including gray PVC sheet options, these colour PVC boards are ideal for nterior design, signage, advertising, and construction. With their excellent weather resistance and low maintenance

Specification

| Name | Pvc foam board |

| Density | 0.35~0.9g/cm |

| Color | White、Customized |

| Place of Origin | Guangzhou,China |

| Main Material | 100% PVC |

| Regular Size | 1220x2440mm (4'x8') or customization |

| Service | OEM |

| Size | 1220*2440mm,1220*1830mm,1000*2000mm,915*1915mm,Customiztion |

| After sales service | 24 Hours On-Line Support |

| Thickness | 1mm,2mm,5mm,8mm,10mm,12mm,15mm,18mm,20mm,etc. |

| Application | Advertising Signage,Outdoor Advertising,Signboard Production, |

| Payment | 30% deposit, 70% balance before shipment. |

| Packing | Carton box or wooden pallet or PE Bag package. |

Product detail

The Science Behind PVC Board Fire Resistance

PVC boards, including compressed PVC boards, closed cell PVC foam boards, and Celuka PVC, are designed with fire-resistant properties. Their composition limits flame spread, while closed cell structures enhance thermal insulation.

Enhancing Water Resistance in PVC Board Manufacturing

In PVC board manufacturing, water resistance is crucial. Expandable PVC offers lightweight durability, while Divinycell foam boards provide excellent buoyancy and moisture resistance. Compressed PVC boards further enhance water repellency, making them ideal for outdoor and marine applications, ensuring longevity and reliability in wet environments.

Exploring the High Hardness of PVC Boards

PVC boards, including popular PVC foam board and polyvinyl chloride foam board, are known for their high hardness, enhancing durability and impact resistance. Ideal for signage and construction, these lightweight boards are suitable for both indoor and outdoor use, with smooth surfaces perfect for printing.

PVC Board Manufacturing: Innovations for Sustainability

Sustainable innovations in PVC boards include compressed PVC for durability, closed cell PVC foam for reduced material use, and efficient Celuka PVC production, all promoting lower emissions and eco-friendly practices in construction.

Techniques for Professional-Grade PVC Board Cutting

Achieving clean, edge-free cuts in PVC boards is essential for a polished finish. Compressed PVC boards require sharp blades to prevent chipping, while closed cell PVC foam boards benefit from fine-toothed saws.

Custom Size PVC Boards: Tailored Solutions for Every Need

Custom-sized PVC boards offer significant benefits for various projects. Divinycell foam boards can be tailored to fit specific dimensions, enhancing efficiency. Compressed PVC boards ensure optimal material use, reducing waste.

Why choose us?

(1)Unmatched Durability: Our compressed PVC boards, closed cell PVC foam boards, and Celuka PVC are designed for exceptional strength, ensuring longevity in all applications.

(2)Tailored Options: We offer customizable sizes and finishes, allowing you to select the ideal product to fit your unique project needs.

(3)Sustainable Solutions: Our commitment to eco-friendly manufacturing practices ensures that you receive high-quality products while minimizing environmental impact.

Raw material

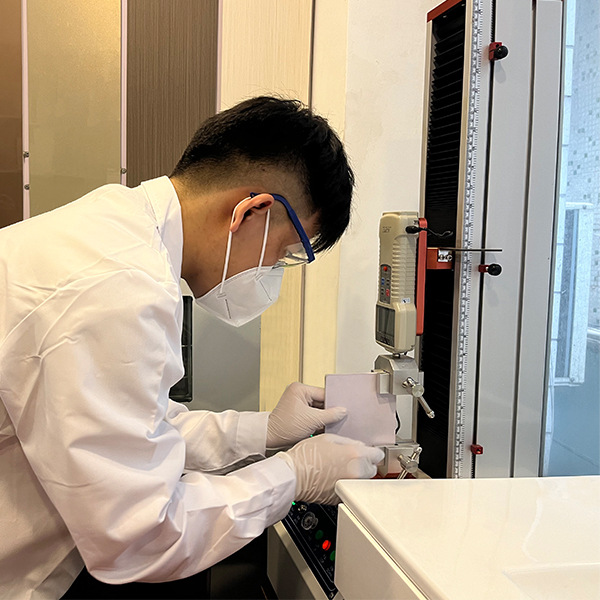

R&D Center

Production equipment

Product warehousing

Production process

(1)Material Selection: High-quality raw materials, including expandable PVC, Divinycell foam board, and compressed PVC board, are carefully sourced to ensure optimal performance and durability in the final product.

(2)Formulation and Mixing: The selected materials are precisely formulated and mixed, allowing for the desired properties, such as strength, flexibility, and insulation, to be achieved.

(3)Shaping and Finishing: The mixture is then shaped using advanced techniques, followed by finishing processes that enhance surface quality and ensure uniformity, resulting in high-quality PVC boards ready for various applications.

Cutting machine tool

Product production

Product production

Product production

Packing & Delivery

(1)Secure Packaging: Our expandable PVC, Divinycell foam board, and compressed PVC board are carefully packaged using sturdy materials to prevent damage during transit, ensuring they arrive in pristine condition.

(2)Custom Solutions: We offer tailored packaging options to accommodate various board sizes and quantities, optimizing space and efficiency for shipping.

(3)Timely Delivery: Our efficient logistics network guarantees prompt delivery, allowing you to receive your PVC boards on schedule for your projects without unnecessary delays.

Wooden pallet packaging

PE bag packaging

FTL

FCL

Applications

(1)Construction and Interiors:

Compressed PVC boards are ideal for structural applications, while Celuka PVC is commonly used for wall panels and decorative finishes, offering durability and aesthetic appeal.

(2)Insulation and Packaging:

Closed cell PVC foam boards provide excellent thermal insulation, making them suitable for refrigeration and packaging applications, ensuring protection against moisture and temperature fluctuations.

(3)Signage and Displays:

The versatility of all three types—compressed PVC, closed cell foam, and Celuka PVC—makes them perfect for signage and display solutions, providing a lightweight yet sturdy option for creative designs.

Screen

Strorage rack

Sign

Green Plants

Our exhibition

(1)Market Exposure: Exhibiting expandable PVC, Divinycell foam board, and compressed PVC boards at trade shows increases visibility, allowing potential customers to discover innovative products and solutions in person.

(2)Networking Opportunities: Trade shows provide a platform to connect with industry professionals, suppliers, and partners, fostering valuable relationships that can lead to collaboration and business growth.

(3)Market Insights: Participating in trade shows allows companies to gain insights into market trends and customer preferences, helping to inform product development and marketing strategies for future success.