Celuka boards offer a smooth surface finish, perfect for signage and interior design. Lightweight yet strong, both Celtec PVC foam boards and Celuka PVC boards ensure easy handling and durability. Their versatility allows for easy customization, fitting various applications in construction and advertising.

Specification

| Name | Pvc foam board |

| Density | 0.35~0.9g/cm |

| Color | White、Customized |

| Place of Origin | Guangzhou,China |

| Main Material | 100% PVC |

| Regular Size | 1220x2440mm (4'x8') or customization |

| Service | OEM |

| Size | 1220*2440mm,1220*1830mm,1000*2000mm,915*1915mm,Customiztion |

| After sales service | 24 Hours On-Line Support |

| Thickness | 1mm,2mm,5mm,8mm,10mm,12mm,15mm,18mm,20mm,etc. |

| Application | Advertising Signage,Outdoor Advertising,Signboard Production, |

| Payment | 30% deposit, 70% balance before shipment. |

| Packing | Carton box or wooden pallet or PE Bag package. |

Product detail

PVC Board Fire Safety: What You Need to Know

When considering fire safety, Celuka boards and Celtec PVC foam boards are engineered with flame-retardant properties, helping to limit fire spread. Celtec PVC boards offer enhanced insulation, reducing heat transfer.

Long-Term Durability of PVC Boards in Water Conditions

Celuka panels and Celuka foam are highly water-resistant, perfect for humid environments. Their closed-cell structure prevents moisture absorption, ensuring long-term durability. Celuka boards maintain their integrity, making them reliable for outdoor and aquatic applications.

Understanding Hardness Ratings in PVC Boards

Hardness ratings are vital for PVC board performance. Celuka boards provide high hardness for excellent impact resistance, while Celtec PVC foam boards balance lightweight design with good rigidity. Knowing these ratings aids in choosing the right material for demanding applications, ensuring durability.

Eco-Labeling and PVC Board Products

Eco-labeling highlights the sustainability of PVC boards. Celuka boards are produced with minimal waste, while Celtec PVC foam boards use less material for lightweight durability. Both options promote energy efficiency and reduce environmental impact, making them ideal for eco-conscious projects.

Achieving Clean Cuts: No-Melt Edges in PVC Boards

Cutting PVC boards like Celuka boards and Celtec PVC foam boards to achieve smooth edges enhances aesthetics and functionality. Smooth-cut edges prevent damage and reduce the risk of injury during handling.

Optimizing Space with Custom Sized PVC Foam Boards

Custom-sized PVC foam boards like Celuka foam, Celuka boards, and Celtec PVC foam boards maximize space efficiency. Tailoring dimensions ensures a perfect fit, reducing waste and enhancing usability. This flexibility supports innovative designs, making them ideal for construction and creative projects.

Why choose us?

(1)Quality Products:

Our Celuka foam, Celuka boards, and Celtec PVC foam boards are manufactured to high standards, ensuring durability and performance for various applications.

(2)Customization Options:

We offer tailored sizes and finishes, allowing you to find the perfect solution for your specific project needs.

(3)Sustainability Commitment:

Our eco-friendly production processes prioritize environmental responsibility, providing you with sustainable materials without sacrificing quality.

Raw material

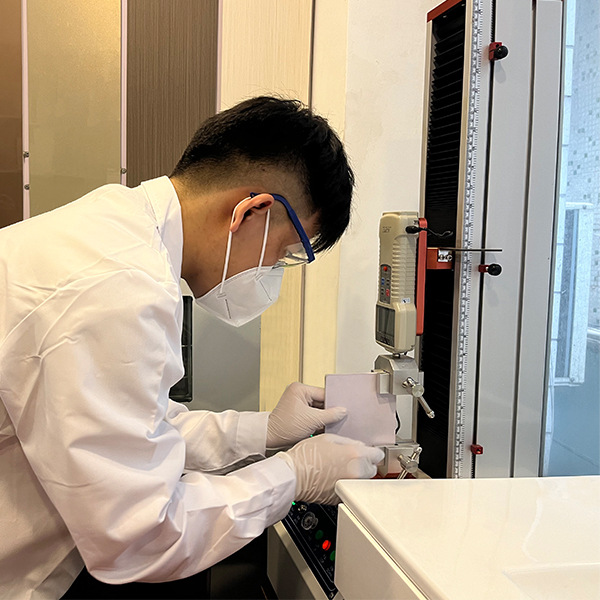

R&D Center

Production equipment

Product warehousing

Production process

(1)Raw Material Selection: We carefully select high-quality materials for Celuka panels, Celuka foam, and Celuka boards to ensure superior durability and performance.

(2)Formulation and Mixing: The selected materials are precisely formulated and mixed to achieve the desired properties, such as strength, insulation, and flexibility.

(3)Shaping and Finishing: The mixture is shaped using advanced techniques, followed by finishing processes that enhance surface smoothness and uniformity, resulting in high-quality PVC boards ready for various applications.

Cutting machine tool

Product production

Product production

Product production

Packing & Delivery

(1)Robust Packaging: Celuka boards, Celtec PVC foam boards, and Celtec PVC boards are securely packaged using durable materials to prevent damage during transit, ensuring they arrive in excellent condition.

(2)Custom Solutions: We offer tailored packaging options to accommodate various board sizes and quantities, optimizing space and efficiency for shipping.

(3)Timely Delivery: Our efficient logistics ensure prompt delivery, allowing you to receive your PVC boards on schedule, minimizing delays for your projects.

Wooden pallet packaging

PE bag packaging

FTL

FCL

Applications

(1)Construction: Celuka boards and Celuka foam are widely used for interior and exterior applications, providing durability and moisture resistance for walls, ceilings, and cladding.

(2)Signage: Celtec PVC foam boards are ideal for signage and displays, offering a lightweight yet sturdy option that can be easily customized for various designs.

(3)Furniture: The versatility of Celuka foam and boards makes them suitable for furniture applications, including cabinets and countertops, where both aesthetics and functionality are essential.

Screen

Strorage rack

Sign

Green Plants

Our exhibition

(1)Increased Visibility: Showcasing Celuka foam, Celuka boards, and Celtec PVC foam boards at trade shows enhances brand exposure, attracting potential customers and industry partners.

(2)Networking Opportunities: Trade shows provide a platform to connect with key industry players, fostering valuable relationships that can lead to collaborations and business growth.

(3)Market Insights: Participating in these events allows companies to gain insights into industry trends and customer preferences, helping to refine products and marketing strategies for future success.