PVC boards for construction, such as 3D PVC foam wall panels and 1/2 PVC foam boards, are transforming the industry. Lightweight yet durable, they are perfect for modern interiors and exterior applications. Offering moisture resistance and easy maintenance, these boards provide both functionality and aesthetic appeal, making them a versatile choice for any project.

Specification

| Name | Pvc foam board |

| Density | 0.35~0.9g/cm |

| Color | White、Customized |

| Place of Origin | Guangzhou,China |

| Main Material | 100% PVC |

| Regular Size | 1220x2440mm (4'x8') or customization |

| Service | OEM |

| Size | 1220*2440mm,1220*1830mm,1000*2000mm,915*1915mm,Customiztion |

| After sales service | 24 Hours On-Line Support |

| Thickness | 1mm,2mm,5mm,8mm,10mm,12mm,15mm,18mm,20mm,etc. |

| Application | Advertising Signage,Outdoor Advertising,Signboard Production, |

| Payment | 30% deposit, 70% balance before shipment. |

| Packing | Carton box or wooden pallet or PE Bag package. |

Product detail

The Role of Additives in PVC Fire Resistance

PVC boards for construction, like 3D PVC foam wall panels and 12 PVC foam boards, utilize flame retardants and thermal stabilizers to enhance fire resistance. These additives ensure the materials resist ignition and minimize smoke, meeting safety standards while providing durable, aesthetically pleasing solutions for various building applications.

Waterproof PVC Boards for Outdoor Use: What You Need to Know

PVC boards for construction, including 3D PVC foam wall panels and 1/2 PVC foam boards, are ideal for outdoor applications due to their excellent waterproof properties. These boards resist moisture, preventing warping and deterioration, making them perfect for various weather conditions. Their durability and low maintenance make them a reliable choice for outdoor projects.

The Role of Additives in PVC Board Hardness

Additives enhance the hardness of PVC boards for construction, like 3D PVC foam wall panels and 1/2 PVC foam boards. By incorporating fillers and stabilizers, these boards achieve improved rigidity and impact resistance, ensuring durability and shape retention for various applications in modern construction.

PVC Board Sheets: Durable and Environmentally Friendly

PVC boards, such as PVC Celuka boards, PVC board sheets, and UV foam boards, are eco-friendly due to their waterproof properties, which prevent mold and decay. Their durability minimizes waste and resource consumption, while eco-conscious production limits harmful chemicals.

Achieving Clean Cuts: No-Melt Edges in PVC Boards

PVC board sheets, including UV and popular PVC foam boards, are easy to cut without melting or deforming. This makes them ideal for applications like signage, displays, and construction. Their smooth, precise edges allow for quick, efficient fabrication, whether for outdoor or indoor use

Custom Size PVC Boards: Tailored Solutions for Every Need

PVC boards for construction, such as 3D PVC foam wall panels and 1/2 PVC foam boards, are durable and environmentally friendly. They are recyclable and have a long lifespan, reducing waste and promoting sustainability in building projects. Choosing PVC boards offers a versatile solution that combines performance with eco-consciousness.

Why choose us?

(1)Exceptional Quality: Our PVC boards for construction, including 3D PVC foam wall panels and 1/2 PVC foam boards, are made from high-grade materials, ensuring durability and long-lasting performance.

(2)Innovative Designs: We offer a range of stylish and functional designs, such as 3D PVC foam wall panels, that enhance both aesthetic appeal and structural integrity in your projects.

(3)Eco-Friendly Solutions: Our products are recyclable and manufactured with sustainable practices, making them an environmentally responsible choice for modern construction needs.

Raw material

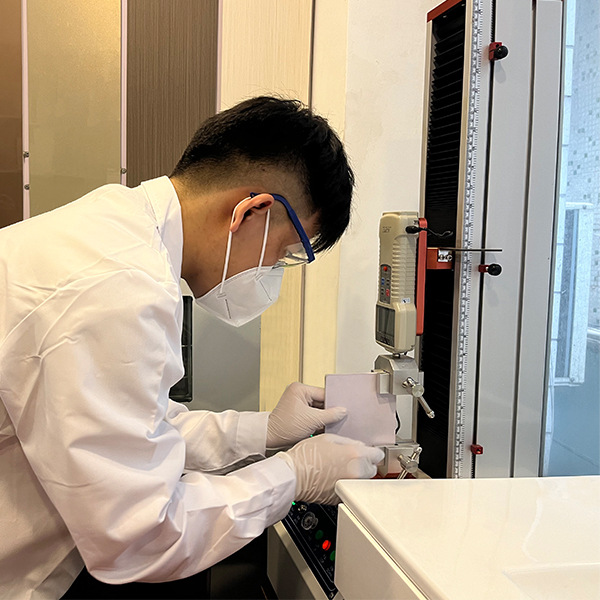

R&D Center

Production equipment

Product warehousing

Production process

(1)Raw Material Preparation: The production of PVC boards for construction begins with high-quality PVC resin, which is blended with additives to enhance properties such as strength and UV resistance.

(2)Extrusion Process: The prepared mixture is heated and extruded through a die to form sheets, including 3D PVC foam wall panels and 1/2 PVC foam boards. This ensures uniform thickness and consistent quality.

(3)Finishing and Quality Control: After extrusion, the boards are cooled, trimmed, and subjected to quality checks. Surface treatments may be applied to improve aesthetics and durability, resulting in a high-quality final product ready for various applications.

Cutting machine tool

Product production

Product production

Product production

Packing & Delivery

(1)Secure Packaging: Our PVC boards for construction, including 3D PVC foam wall panels and 1/2 PVC foam boards, are carefully packed using protective materials to prevent damage during transit.

(2)Efficient Logistics: We employ reliable logistics partners to ensure timely delivery, minimizing delays and ensuring your materials arrive when needed.

(3)Custom Solutions: We offer flexible packing options tailored to your specific order size and shipping requirements, making it easy to handle and transport our products safely.

Wooden pallet packaging

PE bag packaging

FTL

FCL

Applications

(1)Construction: PVC boards for construction are ideal for various structural applications, providing durability and resistance to moisture, making them perfect for walls, ceilings, and flooring.

(2)Interior Design: 3D PVC foam wall panels enhance aesthetic appeal in residential and commercial spaces, offering creative solutions for interior decoration with easy installation and maintenance.

(3)Signage: 12 PVC foam boards are widely used for signage and displays due to their lightweight nature, versatility, and ability to withstand outdoor conditions, making them suitable for advertising and branding.

Screen

Strorage rack

Sign

Green Plants

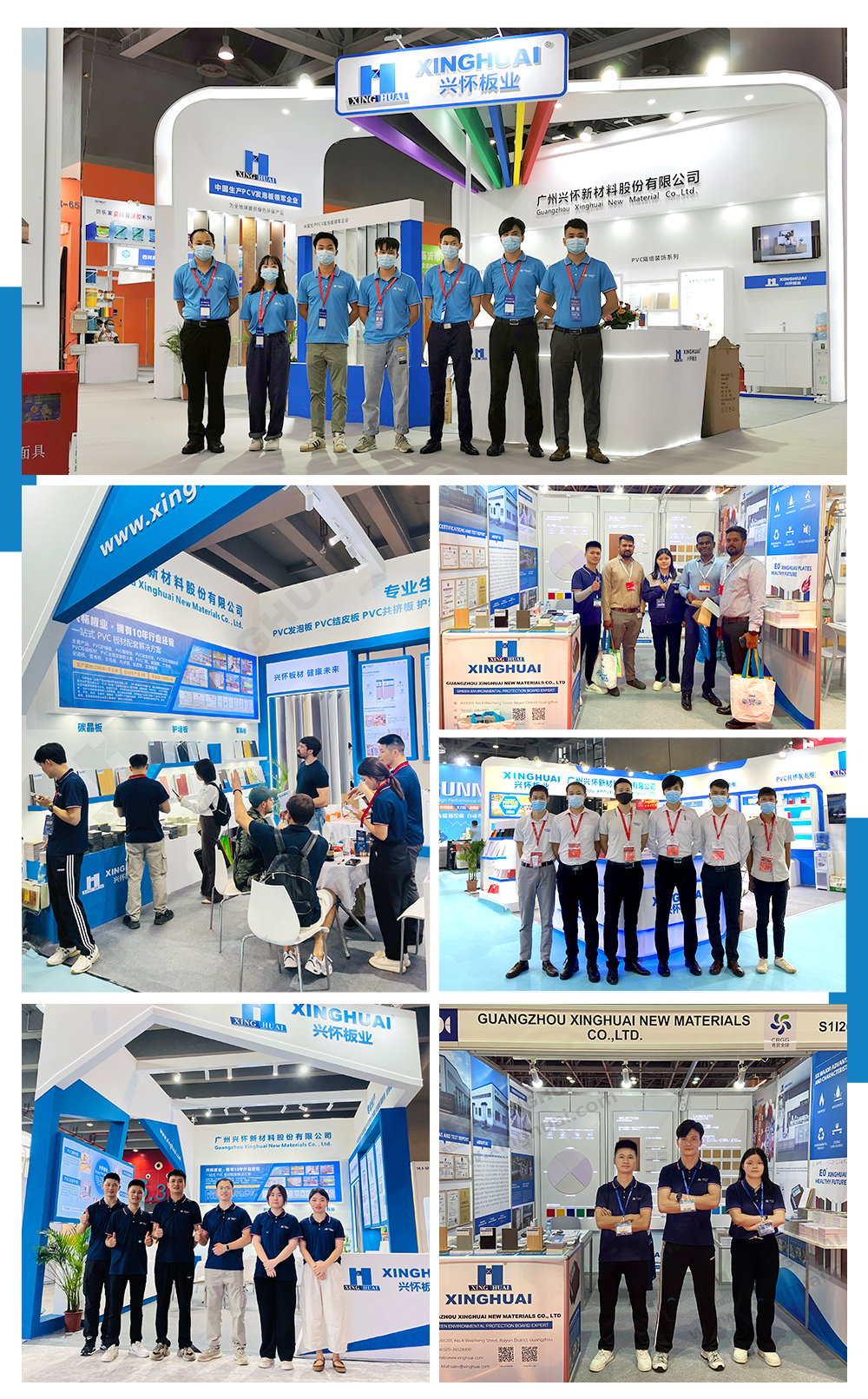

Our exhibition

(1)Market Exposure: Exhibiting PVC boards for construction, including 3D PVC foam wall panels and 12 PVC foam boards, increases brand visibility and connects with potential customers and industry professionals.

(2)Networking Opportunities: Trade shows provide valuable networking opportunities, allowing us to forge relationships with suppliers, contractors, and other stakeholders in the construction industry.

(3)Product Demonstration: Participating in trade shows allows us to showcase the features and benefits of our products, such as their durability and design versatility, helping to educate potential clients and drive sales.