In the realm of building materials and industrial applications, waterproof performance is a critical factor that determines the suitability of a material for specific environments. When comparing PVC co-extruded sheets with ordinary sheets, a common question arises: Is the waterproof performance of PVC co-extruded sheets better than that of ordinary sheets? The answer is a resounding yes, and this superiority is closely linked to the unique properties of materials like pvc co extruded foam board, extruded pvc sheet, rigid expanded pvc, laminated pvc ceiling, and pvc coated foam board. These materials showcase how advanced manufacturing techniques enhance waterproof capabilities, making PVC co-extruded sheets stand out in wet and humid environments.

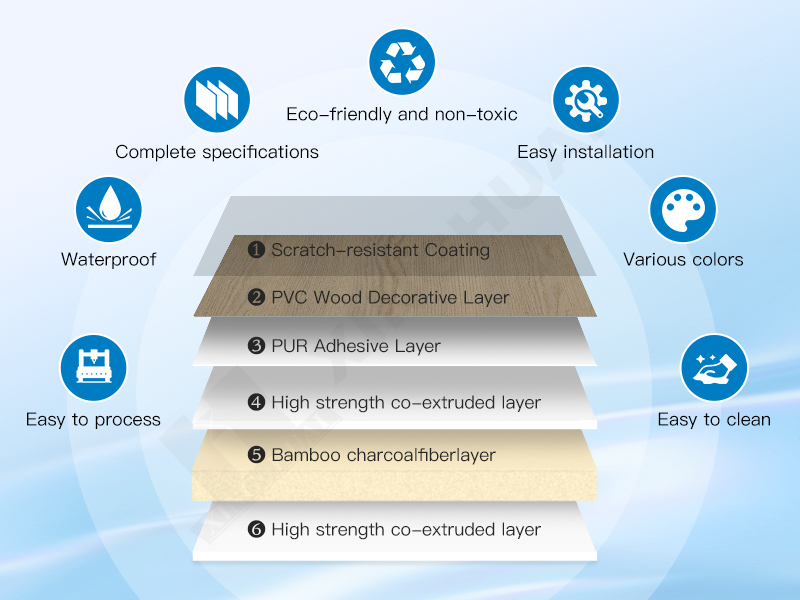

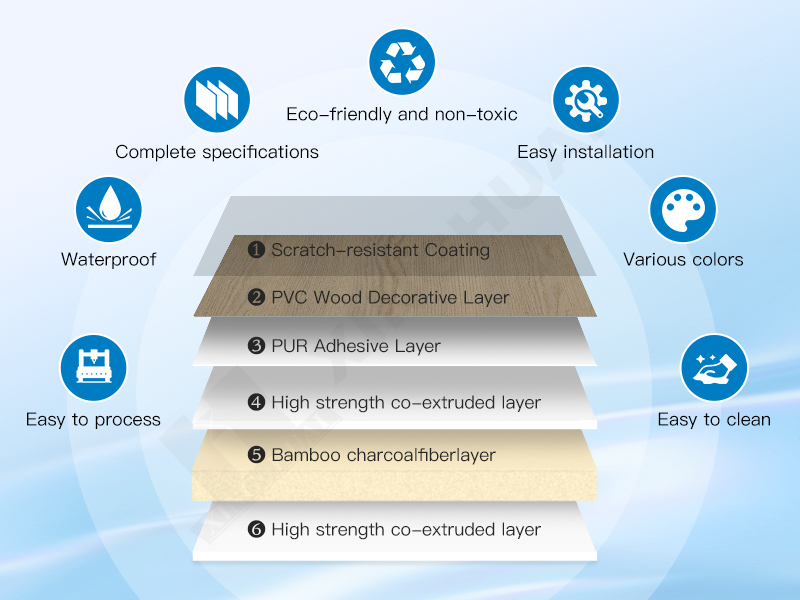

PVC co-extruded sheets are engineered with multiple layers of PVC materials, each designed to contribute to overall performance, with waterproofing being a key focus. Unlike ordinary sheets, which often consist of a single layer of material, pvc co extruded foam board features a structured composition where the core and surface layers work together to prevent water penetration. The co-extrusion process ensures that the layers bond seamlessly at a molecular level, eliminating gaps and seams that could allow water to seep through— a common vulnerability in ordinary sheets. This structural advantage immediately sets PVC co-extruded sheets apart, providing a solid foundation for superior waterproof performance compared to their ordinary counterparts.

Extruded pvc sheet, a fundamental component in many co-extruded products, inherently possesses excellent waterproof properties due to the nature of PVC and the extrusion manufacturing process. Extruded pvc sheet is produced by melting PVC resin and forcing it through a die, creating a dense, homogeneous structure with minimal porosity. This dense structure resists water absorption far better than the more porous composition of many ordinary sheets, which may be made from materials like paper, wood, or lower-grade plastics. When used as part of a co-extruded system, extruded pvc sheet forms a reliable barrier against moisture, reinforcing the waterproof performance that makes PVC co-extruded sheets superior to ordinary sheets.

Rigid expanded pvc is another material that highlights the waterproof advantages of PVC co-extruded sheets. While rigid expanded pvc contains a foam-like structure with internal air pockets, these pockets are completely encapsulated within the PVC matrix, preventing water from entering the core. The rigid nature of this material ensures that it maintains its shape and structural integrity even when exposed to water, unlike ordinary sheets that may warp, swell, or degrade when wet. Rigid expanded pvc used in co-extruded sheets retains its waterproof properties over time, whereas ordinary sheets often experience a rapid decline in performance after repeated exposure to moisture.

Laminated pvc ceiling products demonstrate how PVC co-extruded sheets excel in waterproofing for specific applications. Laminated pvc ceiling panels are designed to withstand the humid conditions found in bathrooms, kitchens, and basements— environments where ordinary ceiling sheets often fail due to water damage. The lamination process, combined with the co-extruded core, creates a surface that repels water and prevents moisture from penetrating into the underlying structure. Unlike ordinary ceiling sheets that may absorb water and develop mold or mildew, laminated pvc ceiling panels remain unaffected by condensation and splashes, maintaining their appearance and functionality for years. This real-world application clearly shows that the waterproof performance of PVC co-extruded sheets used in laminated pvc ceiling systems outperforms ordinary sheets in the same setting.

Pvc coated foam board takes waterproofing a step further by adding a specialized coating layer to the surface of foam board, a technique often integrated into co-extruded designs. The coating on pvc coated foam board acts as an additional barrier, enhancing the natural waterproof properties of the underlying foam core. This dual protection— the foam core resisting water absorption and the coating repelling surface water— is far more effective than the single-layer defense of ordinary sheets. Pvc coated foam board, as part of a co-extruded system, ensures that even if water comes into contact with the surface, it beads up and runs off rather than soaking in, a behavior rarely seen in ordinary sheets that lack such protective coatings.

The molecular structure of PVC itself contributes significantly to the waterproof performance of co-extruded sheets. PVC is a non-porous material, meaning it does not have tiny openings that allow water molecules to pass through, unlike the cellulose-based or porous materials used in many ordinary sheets. When combined with the co-extrusion process, which creates a continuous, unbroken PVC matrix, the result is a sheet that is inherently resistant to water. Ordinary sheets, even those made from plastics, often use lower-quality polymers with more porous structures or contain additives that reduce their waterproof capabilities, making them no match for the waterproof performance of PVC co-extruded sheets.

In applications where sheets are exposed to standing water or frequent wetting, PVC co-extruded sheets prove their superiority time and again. For example, pvc co extruded foam board used in shower surrounds or poolside applications remains unaffected by constant contact with water, while ordinary sheets would quickly deteriorate. The seamless edges and joints of PVC co-extruded sheets, achieved through precise manufacturing, prevent water from seeping into installation gaps— a problem that plagues ordinary sheets, which often require additional sealants that degrade over time. This ability to maintain waterproof integrity in continuous wet conditions is a key reason why PVC co-extruded sheets outperform ordinary sheets.

Extruded pvc sheet used in co-extruded products maintains its waterproof properties even when subjected to temperature fluctuations, another area where ordinary sheets struggle. In environments where temperatures rise and fall, causing condensation, extruded pvc sheet remains stable, resisting the moisture that would cause ordinary sheets to absorb water and degrade. The dimensional stability of extruded pvc sheet ensures that it does not expand or contract excessively, preserving the waterproof barriers within the co-extruded structure. Ordinary sheets, lacking this stability, extruded pvc sheet may develop cracks or gaps as they expand and contract, compromising their ability to resist water over time extruded pvc sheet.

Rigid expanded pvc in co-extruded sheets offers long-term waterproof performance that ordinary sheets simply cannot match. Unlike ordinary sheets that may have initial water resistance but lose it as the material ages, rigid expanded pvc retains its waterproofing capabilities for the lifespan of the product. This longevity is due to the chemical stability of PVC, extruded pvc sheet which does not react with water or break down in humid conditions extruded pvc sheet. Ordinary sheets, especially those made from organic materials, are prone to biodegradation when exposed to moisture, leading to the growth of mold and mildew that further waterproofing. Rigid expanded pvc in co-extruded sheets resists such degradation, ensuring consistent waterproof performance.

Laminated pvc ceiling systems not only resist water on their surface but also prevent moisture from affecting the area behind them, a critical advantage over ordinary ceiling sheets. When ordinary sheets absorb water, they can transfer moisture to the underlying structure, causing damage to walls and framing. Laminated pvc ceiling panels, however, act as a complete moisture barrier— their co-extruded core and laminated surface prevent both surface water and vapor from passing through. This protection helps maintain the integrity of the entire building structure, whereas ordinary sheets often act as a conduit for moisture, leading to costly repairs. This comprehensive moisture management is a hallmark of PVC co-extruded sheets’ superior waterproof performance.

Pvc coated foam board used in co-extruded applications provides enhanced extruded pvc sheet resistance to water under pressure, extruded pvc sheet such as in heavy rain or water spray scenarios. The coating on pvc coated foam board creates a smooth, impermeable surface that water cannot penetrate, extruded pvc sheet even when subjected to force. Ordinary sheets, without such a protective coating, may allow water to soak in when exposed to pressure, leading to internal damage and reduced performance. extruded pvc sheet Whether used in outdoor signage, exterior cladding, or wet-area partitions,extruded pvc sheet pvc coated foam board in co-extruded form maintains its waterproof barrier, outperforming ordinary sheets in demanding conditions.

The manufacturing process of PVC co-extruded sheets allows for the integration of additives that specifically enhance waterproof performance, an advantage not typically found in ordinary sheets. These additives can include UV stabilizers that prevent degradation from sunlight (which can compromise waterproofing in ordinary sheets), as well as hydrophobic agents that further reduce water absorption extruded pvc sheet . Pvc co extruded foam board often incorporates such additives throughout its layers, ensuring that the waterproof properties are consistent across the entire sheet. Ordinary sheets rarely benefit from such targeted enhancements, extruded pvc sheet limiting their ability to resist water effectively over time.