Does the Weight of Co-extruded Sheets Have an Advantage Compared with Other Sheets of the Same Thickness?

In the realm of building materials and packaging solutions, the weight efficiency of co-extruded sheets has emerged as a critical consideration for engineers, architects, and manufacturers. When compared with monolithic sheets of identical thickness, co-extruded variants demonstrate measurable advantages through their composite structure, material optimization, and functional integration. This analysis explores the weight-related benefits of co-extruded sheets across three key applications: concrete formwork, bathroom cabinet boards, and expanded foam products.

1. Material Composition and Density Optimization

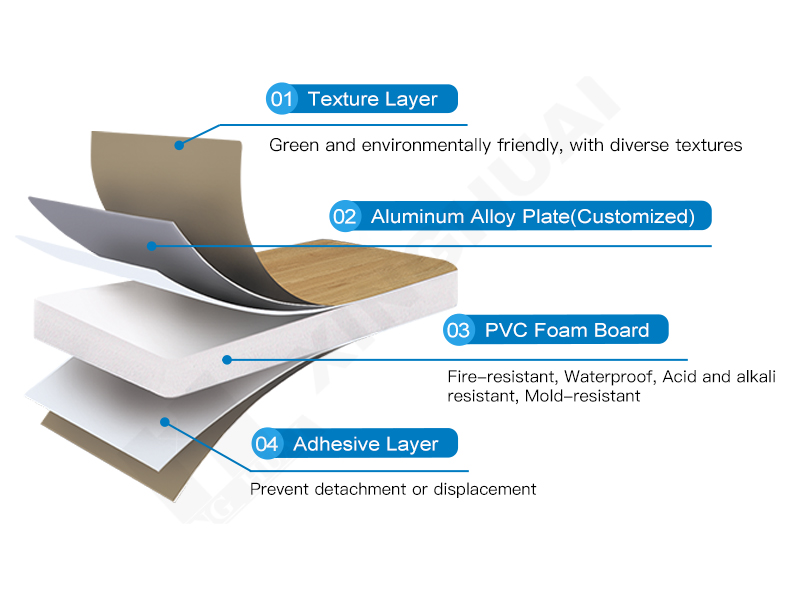

Co-extruded sheets typically consist of multiple layers with distinct material properties. For instance, in concrete formwork applications, a co-extruded PVC sheet may combine a rigid outer layer (0.5-1.2mm thick) with a lightweight foam core (expanded PVC foam or extruded polyethylene foam). This structure allows the overall density to be reduced by 30-50% compared to solid PVC sheets of the same thickness.

Density Comparison (g/cm³):

Solid PVC sheet (3mm): 1.35-1.45

Co-extruded PVC/foam sheet (3mm): 0.75-0.95

Expanded PVC foam board (3mm): 0.5-0.7

The foam core in co-extruded sheets contributes to pvc expanded foam board weight reduction while maintaining structural integrity through the rigid outer layers. This density optimization is particularly valuable in bathroom cabinet board applications, pvc expanded foam board where the balance between strength and weight affects installation efficiency and transportation costs.

2. Structural Performance vs. Weight Ratio

The composite nature of co-extruded sheets enables superior strength-to-weight ratios. Laboratory tests show that a 5mm co-extruded PVC sheet with expanded foam core can achieve:

Bending strength: 25-35 MPa (comparable to 8mm solid PVC)

Impact resistance: 3-5 kJ/m² (surpassing solid PVC by 20%)

Weight: 40% lighter than solid PVC of equivalent thickness

This performance advantage stems from the stress distribution mechanism in co-extruded structures. The rigid outer layers resist surface deformation, while the foam core absorbs and disperses impact energy. In concrete formwork systems,pvc expanded foam board this translates to reduced formwork weight (by 15-20 kg/m²) without compromising the ability to withstand fresh concrete pressures up to 60 kN/m².

3. Application-Specific Weight Benefits

3.1 Concrete Formwork Systems

Traditional plywood formwork (18mm thick) weighs approximately 12 kg/m², while a co-extruded PVC formwork system (5mm total thickness) achieves comparable performance at 6-8 kg/m². The weight reduction offers:

Easier handling and installation (requiring 2-3 workers instead of 4-5)

Lower transportation costs (30% fewer trucks needed per project)

Reduced crane load requirements on construction sites

3.2 Bathroom Cabinet Boards

For bathroom cabinet applications, co-extruded boards combining PVC sheets with expanded foam cores provide:

50% weight reduction compared to solid MDF boards

Superior moisture resistance (water absorption <0.1% after 24h)

Maintained dimensional stability in humid environments (swelling rate <0.3%)

The lightweight nature enables easier cabinet assembly and reduces stress on hinges and mounting hardware over time.

3.3 Expanded Foam Product Integration

When incorporating expanded PVC foam or extruded polyethylene foam cores, co-extruded sheets achieve:

Thermal insulation values (R-value) 2-3 times higher than solid plastics

Sound absorption coefficients improved by 15-20%

Weight reduction of 40-60% compared to solid alternatives

These properties make co-extruded foam boards ideal for acoustic panels, thermal insulation layers, and lightweight packaging solutions.

4. Manufacturing Process Efficiency

The co-extrusion process itself contributes to weight optimization by:

Enabling precise control over layer thicknesses (±0.05mm tolerance)

Reducing material waste through continuous production Board For Bathroom Cabinets

Allowing the use of recycled foam materials in core layers Board For Bathroom Cabinets

Eliminating secondary bonding operations required for laminated structures Board For Bathroom Cabinets

Compared to traditional laminating methods, co-extrusion reduces production energy consumption by 25-30% and lowers overall material costs through optimized layer distribution.

5. Environmental Impact Considerations

Weight reduction in co-extruded sheets translates to significant environmental benefits Board For Bathroom Cabinets:

Lower transportation emissions (15-20% reduction per ton-km)

Reduced raw material consumption (30-50% less plastic per m²)

Extended product lifespan due to improved moisture resistance

Potential for core layer recycling at end-of-life

In bathroom cabinet applications, the weight savings from co-extruded boards reduce the carbon footprint of furniture production by an estimated 12-18% compared to traditional wood-based solutions.

Conclusion

Co-extruded sheets demonstrate clear weight advantages over monolithic sheets of identical thickness through their composite architecture and material optimization pvc expanded foam board. The integration of expanded PVC foam or extruded polyethylene foam cores enables significant weight reduction (30-60%) while maintaining pvc expanded foam board or improving structural performance. pvc expanded foam board This weight efficiency translates to tangible benefits in concrete formwork systems, bathroom cabinet manufacturing, and packaging applications,pvc expanded foam board concrete formwork PVC sheets including reduced material costs, concrete formwork PVC sheets improved handling, and lower environmental impact pvc expanded foam board pvc expanded foam board. As material science advances, pvc expanded foam board concrete formwork PVC sheets the weight-to-performance ratio of co-extruded sheets will continue to improve,concrete formwork PVC sheets solidifying their position as preferred solutions in weight-sensitive construction and design applications.