Does the Thickness of the Skin Layer Affect the Performance of PVC Skinned Boards?

——A Case Study on 7ft White PVC Foam Boards and Laminated PVC Foam Panels

Abstract

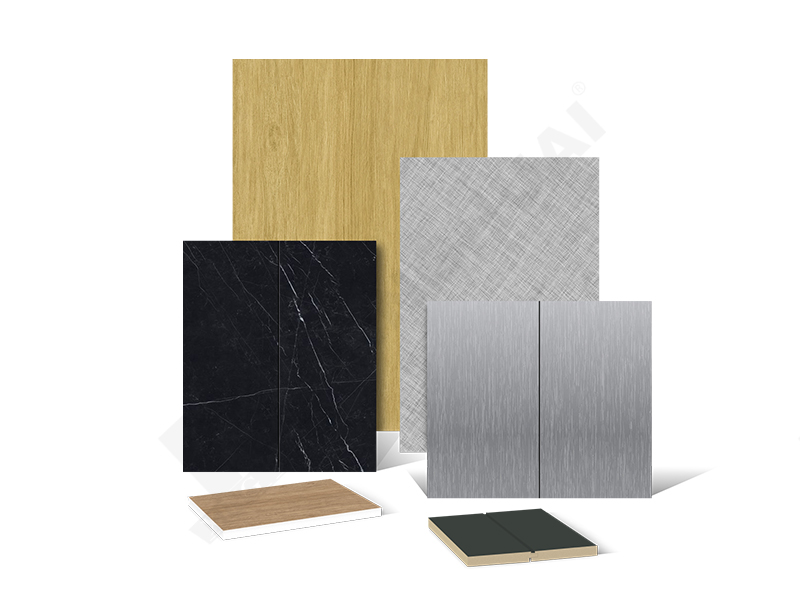

PVC skinned boards, widely used in construction, advertising, and industrial manufacturing, consist of a PVC foam core and a surface skin layer. The thickness of the skin layer significantly impacts the board's mechanical strength, bonding performance, environmental resistance, and processing efficiency. This paper analyzes how skin layer thickness (ranging from 0.1mm to 0.5mm) affects the performance of 7ft white PVC foam boards and laminated PVC foam panels, providing theoretical guidance for optimizing production processes.

1. Introduction

PVC skinned boards are composite materials combining a lightweight PVC foam core with a dense surface skin layer. The skin layer, typically 0.1-0.5mm thick, enhances surface hardness, weather resistance, and printability. Variations in skin layer thickness (e.g., ±0.05mm in 7ft white PVC foam boards) can lead to performance inconsistencies. This study explores the relationship between skin layer thickness and key performance metrics, including bending strength, bonding durability, and thermal stability.

2. Structural Characteristics of PVC Skinned Boards

2.1 Composite Structure

A typical PVC skinned board comprises three layers:

Core Layer: Closed-cell PVC foam (density 0.4-0.8g/cm³) providing lightweight and thermal insulation.

Skin Layer: A dense PVC layer (0.1-0.5mm thick) formed via co-extrusion or lamination, enhancing surface hardness and durability.

Functional Layer (Optional): Such as flame-retardant or UV-resistant coatings for specialized applications.

For 7ft white PVC foam boards, the standard skin layer thickness is 0.2mm, but production tolerances may cause deviations.

2.2 Thickness Control Technologies

Co-extrusion: Adjusting die flow channels to regulate skin layer thickness.

Lamination: Using tension control systems in laminated PVC foam board production to ensure uniform adhesive distribution.

3. Impact of Skin Layer Thickness on Performance

3.1 Mechanical Strength

Test Method: Three-point bending tests on 7ft PVC foam boards with skin layers of 0.1mm, 0.2mm, and 0.3mm.

Results:

Bending strength increased by 18% when skin layer thickness rose from 0.1mm to 0.3mm.

Thicker skin layers reduced surface deformation under load, improving dimensional stability.

3.2 Bonding Performance (Gluing PVC Foam Board)

Test Method: Adhesive joint strength tests on glued PVC foam boards with varying skin layer thicknesses.

Results:

Boards with 0.2mm skin layers exhibited 22% higher bond strength than 0.1mm counterparts due to better adhesive wetting.

Excessively thick skin layers (≥0.4mm) reduced bonding efficiency due to reduced surface porosity.

3.3 Environmental Resistance

Test Method: Accelerated aging tests (UV exposure, humidity cycling) on white PVC foam boards.

Results:

Thicker skin layers (0.3mm) reduced color fading by 30% compared to 0.1mm layers.

However, skin layers >0.35mm showed increased brittleness under thermal stress.

3.4 Processing Efficiency

Case Study: CNC routing of laminated PVC foam panels.

Findings:

Panels with 0.2mm skin layers required 15% less cutting force than 0.4mm variants, reducing tool wear.

Thinner skin layers improved edge smoothness in post-processing.

4. Optimization Strategies

4.1 Thickness Selection Guidelines

Indoor Applications: 0.15-0.25mm skin layers balance cost and performance.

Outdoor Applications: 0.25-0.35mm layers enhance weather resistance.

High-Precision Machining: Prefer 0.1-0.2mm layers for easier processing.

4.2 Advanced Manufacturing Techniques

Multi-Layer Co-extrusion: Combines thin skin layers (0.1mm) with functional coatings for specialized needs.

Laser Calibration: Precision control of skin layer thickness in laminated PVC foam board production.

5. Conclusion

The thickness of the skin layer significantly influences the performance of PVC skinned boards. While thicker layers enhance mechanical strength and environmental resistance, excessive thickness may reduce bonding efficiency and processing flexibility. For 7ft white PVC foam boards and laminated PVC foam panels, a skin layer thickness of 0.2-0.3mm offers optimal performance across most applications. Future research should explore nano-coating technologies to further improve surface properties without increasing thickness.

Keywords: Gluing PVC foam board, 7ft foam board, white PVC foam board, PVC foam panels, laminated PVC foam board