1. Material Composition and Structural Advantages

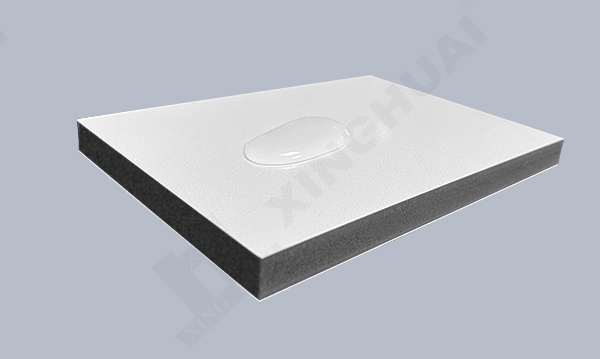

PVC co-extruded sheets are manufactured through a co-extrusion process, where multiple layers of PVC resin are fused into a single board. Typically, this involves a rigid outer layer (non-foamed) and a foamed inner core, creating a "sandwich" structure. The expanded PVC foam core provides lightweight insulation and impact resistance, while the dense surface layers enhance scratch resistance, gloss, and printability. For instance, white expanded PVC sheets are widely used in advertising and décor due to their uniform color and smooth finish, which supports direct digital printing without lamination.

The co-extrusion process also enables customization of thickness, density, and surface hardness. A 4 x 8 foam core board (standard size) can be engineered with varying foam-to-rigid ratios, balancing cost and performance. This adaptability is crucial for secondary processing, as it ensures the material retains structural integrity during modifications.

2. Secondary Processing Capabilities

Secondary processing refers to post-extrusion modifications such as cutting, drilling, thermoforming, or surface treatments. PVC co-extruded sheets excel in this domain due to their homogenous composition and thermal stability.

Mechanical Processing

Cutting and Drilling: The rigid surface layers of co-extruded sheets resist chipping during sawing or CNC routing, making them ideal for precision fabrication. A 4 x 8 foam core board can be easily trimmed to custom sizes for furniture or signage Fire Retardant PVC Board.

Thermoforming: The foam core’s low melting point allows it to be heated and molded into complex shapes, such as curved panels for automotive interiors or architectural elements 4 x 8 foam core board.

Joining Techniques: Sheets can be welded, screwed, or adhesively bonded. The Fire Retardant PVC Board variant, often used in public spaces, maintains bond strength even under high-temperature conditions.

Surface Treatments

Printing and Engraving: The smooth, Fire Retardant PVC Board non-porous surface of white expanded PVC sheets supports high-resolution printing, UV coating, and laser engraving. This makes them popular for retail displays and branded décor.

Lamination: While co-extruded sheets often eliminate the need for lamination due to their hard surface, additional films can be applied for textured finishes or enhanced durability 4 x 8 foam core board.

Fire Retardancy and Safety

The Fire Retardant PVC Board variant undergoes chemical treatment to meet international safety standards (e.g., UL94 V-0). This property is preserved during secondary processing,Fire Retardant PVC Board ensuring compliance in applications like hospital partitions or transportation interiors 4 x 8 foam core board.

3. Industry-Specific Applications

The secondary processability of PVC co-extruded sheets has driven their adoption across sectors:

Construction: Cut-to-size panels for waterproof wall cladding, with edges routed for hidden fasteners.

Furniture: CNC-machined components for modular cabinets, 4 x 8 foam core board leveraging the material’s lightweight yet rigid structure.

Transportation: Thermoformed dashboard panels in buses and subways, combining flame resistance with aesthetic appeal.

Advertising: Direct-printed expanded PVC boards for outdoor billboards, 4 x 8 foam core board resistant to UV degradation and moisture.

4. Technical Considerations

While PVC co-extruded sheets are highly processable, certain parameters must be controlled:

Temperature Management: Overheating during thermoforming can degrade the foam core. Processors must adhere to recommended heating zones (typically 140–180°C).

Tooling Selection: Carbide-tipped blades are preferred for cutting to prevent melting and edge deformation.

Waste Reduction: Offcuts from secondary processing can be recycled into new PVC compounds, aligning with sustainability goals.

Conclusion

PVC co-extruded sheets are not only viable but ideal for secondary processing. Their layered structure, thermal stability, and inherent properties like fire retardancy and moisture resistance make them adaptable to diverse fabrication needs. Whether transformed into a 4 x 8 foam core board 4 x 8 foam core board for architectural elements or a Fire Retardant PVC Board for safety-critical applications, these sheets offer a cost-effective, durable solution 4 x 8 foam core board. As industries demand more customized and sustainable materials, the secondary processability of PVC co-extruded sheets will remain a key driver of their widespread adoption.